Aluminium: The Lightweight Metal Driving a Heavyweight Transition

Aluminium is all around us – in cans, cars, cables and construction. But behind its low weight lies a high-impact industry. As global efforts accelerate towards net-zero targets, aluminium’s unique properties are making it increasingly essential – and raising critical questions about how sustainably we can meet future demand.

Get the essentials in minutes – just press play.

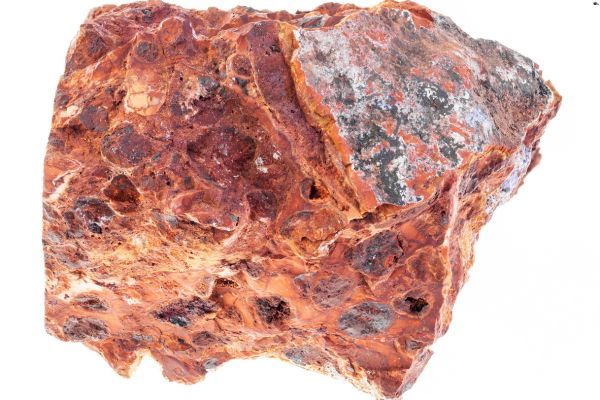

The World’s Most Common Metal, Once Worth More Than Gold

Aluminium is the most abundant metal in the Earth’s crust, yet until the late 1800s, it was considered more precious than gold. The breakthrough came with the development of the Hall–Héroult process in 1886, which enabled commercial production. Since then, aluminium has become integral to modern life – from aerospace to kitchen foil.

Light, Strong, and Infinitely Recyclable

Aluminium’s strength-to-weight ratio, resistance to corrosion, and conductivity make it indispensable across sectors. Crucially, it is 100% recyclable without degrading in quality. These characteristics make it not only valuable for industry, but also key to the circular economy and the fight against single-use plastics and high-carbon materials like steel.

A Key Metal for the Green Transition

As the world decarbonises, aluminium demand is rising sharply. Electric vehicles, solar panel frames, wind turbine housings, and energy-efficient buildings all rely on aluminium. It is also increasingly used in battery casings. The International Energy Agency (IEA) identifies aluminium as one of the metals essential to delivering net-zero ambitions.

High Energy Costs: The Production Challenge

Aluminium’s downside is its energy intensity. Producing primary aluminium requires roughly 40% more energy than copper. Energy costs can account for up to 40% of total production costs, and around 60% of global production still depends on fossil fuels. Unless this shifts towards renewables, aluminium’s full sustainability potential remains out of reach.

Recycling: The Most Effective Solution

Fortunately, recycled aluminium uses up to 95% less energy than primary production. Global investment in closed-loop recycling systems is growing, particularly in packaging and the automotive industry. The IEA estimates that by 2030, 42% of aluminium supply will come from recycled sources – a vital step towards decarbonisation.

Resource Security and Environmental Concerns

While aluminium is plentiful, challenges remain. Smelting capacity, energy prices, and environmental regulations vary significantly across regions. Mining also raises concerns around biodiversity loss, water usage, and community displacement, particularly in countries lacking strong environmental protections.

Conclusion

Aluminium is a cornerstone of modern infrastructure and a catalyst for clean technology. Its role will only grow in a low-carbon economy. However, meeting future demand sustainably will require greater investment in renewable-powered smelting, recycling infrastructure, and responsible sourcing. Aluminium may be light, but its future carries serious weight.